Among other pump types, the Gear Pump is a common choice for industrial applications.

What is a Gear Pump?

The gear pump was invented by Johannes Kepler in the early 17th century. This hydraulic pump is mainly used in power transmission applications. It operates by receiving drive power from the drive shaft of a truck, lorry, or electric motor. In this way, mechanical energy is converted into hydraulic energy. In addition, it generates high pressure against the resistance in front of it.

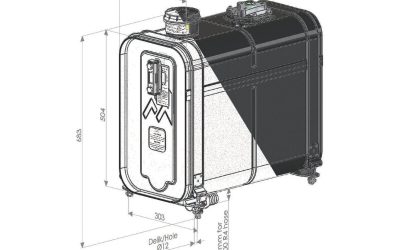

Among positive displacement pumps, this type is one of the most widely used. Inside a gear pump, there are two gears: one driving gear and one idler gear. These gears are mounted parallel to each other. The teeth on the outer surface of the gears direct the flow of the oil. The sliding bearings mounted on the pump body and cover keep the gears fixed on their central axis.

Furthermore, the body and cover parts surrounding the gears guide the flow of hydraulic oil. The suction and discharge ports in the body transfer the oil. This ensures efficient system operation.

Working Principle

The pump is driven by the power it receives from a truck, lorry, or electric motor. Then, two intermeshing gears begin to rotate, initiating the movement of hydraulic oil. As the gears rotate and separate, a partial vacuum is created that fills with oil. Thus, the oil moves from the suction port into the body.

Narrow clearances and high rotational speed minimize back leakage of the oil. As the gears continue to rotate, they trap the oil and carry it around the casing from the suction port to the discharge port. Thanks to their robust design, these pumps operate safely even at very high pressures. Moreover, they can easily pump high-viscosity oils.

Applications

This type of pump provides reliable solutions in different industries. It is widely used especially in agricultural machinery, industrial production lines, and mobile hydraulic systems. In addition, it performs effectively in heavy-duty machinery and vehicles. These include applications for lubrication, lifting, and pressure demands.

Thanks to their compact design, they can also be used comfortably in limited spaces. Their durable structure ensures long-lasting performance and reduces maintenance needs. Therefore, this pump type provides both cost advantages and reliability, making it a preferred solution.

Conclusion

With its simple design and high performance, the gear pump is among the indispensable components in hydraulic systems.

gear pump

gear pump