Hydraulic Systems: The Source of Power in Industry

Hydraulic systems stand out as an indispensable technology in modern industry. These systems produce mechanical work by using the movement of fluids under pressure. They are widely preferred especially in construction machinery, agricultural equipment, the automotive sector, and industrial machines. Moreover, they provide reliable solutions even under harsh conditions such as mining and maritime.

Basic Components of Hydraulic Systems

Hydraulic Pump

Hydraulic pumps generate the pressurized fluid that feeds the system. By converting mechanical energy into hydraulic energy, they power the system. Hidromas ensures high efficiency with its piston pumps and telescopic cylinders. In addition, telescopic cylinders save space with their compact design while offering wide movement range, providing advantages in many applications.

Hydraulic Cylinder

Hydraulic cylinders convert pressurized fluid into linear motion. Hidromas provides strong solutions with cylinders of different sizes and capacities for both construction machinery and industrial production lines. On the other hand, with their special designs, they operate safely even under tough conditions.

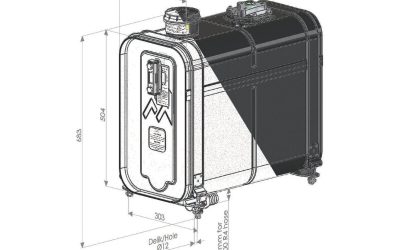

Hydraulic Oil Tank

Oil tanks enable fluid storage and filtration. Hidromas tanks, with their high capacities, support safe system operation. Moreover, they maintain temperature and pressure balance, extending service life. As a result, maintenance costs decrease and the system operates efficiently for longer.

Filters

Filters capture dirt and particles in the system, preventing damage to components. Hidromas filters provide high efficiency, increasing performance. Thus, the lifespan of the system extends and unexpected failures are minimized.

Hoses and Fittings

Hoses and fittings enable fluid transfer and secure connections. Hidromas products stand out with their sealing properties. Furthermore, their high pressure resistance gives users confidence.

Applications of Hydraulic Systems

Construction Machinery

Excavators, loaders, and cranes require high power. Hydraulic systems provide precise and reliable movements in these machines. Moreover, Hidromas pumps and cylinders deliver long-lasting performance under heavy-duty conditions.

Agricultural Equipment

Tractors, harvesters, and spraying systems benefit from hydraulic technology. Hidromas telescopic cylinders increase efficiency in the agricultural sector. In addition, their durability provides farmers with long-term solutions.

Automotive Industry

Steering, braking, and suspension systems are among the most important examples of hydraulic technology. Hidromas components enhance vehicle safety and driving comfort. At the same time, thanks to energy efficiency, they help reduce fuel consumption.

Industrial Machinery

Press, injection, and lifting machines require hydraulic systems. Hidromas solutions ensure high efficiency in these machines. Consequently, production continuity increases and operating costs decrease.

Mining

Drilling, rock crushing, and transportation systems require high pressure. Hidromas pumps provide reliability in these harsh conditions. Especially, their durable materials ensure long-term usage.

Maritime

In ships, steering systems, cranes, and hatch mechanisms operate with hydraulic solutions. Hidromas makes a difference in the maritime sector with its corrosion-resistant products. Moreover, thanks to reliable performance, maintenance intervals are extended.

Hydraulic Pump: Hidromas Quality and Reliability

Hydraulic pumps, as the heart of the system, make energy transfer possible. Therefore, choosing the right pump is of great importance. Hidromas stands out in the industry by combining quality and reliability.

Functions of Hydraulic Pumps

Pumps convert mechanical energy into hydraulic energy, generating pressurized fluid. Thus, other components in the system operate. They also provide energy efficiency and precise control.

Types of Hydraulic Pumps

-

Piston Pumps: Suitable for heavy industry with high pressure and flow rates.

-

Gear Pumps: Widely used thanks to their simple design and reliability.

-

Vane Pumps: Known for quiet operation and low vibration levels.

Hidromas Hydraulic Pump Products

-

High Pressure Resistance: Works safely in heavy industry and construction.

-

Long Life: Reduces maintenance costs with quality manufacturing processes.

-

Energy Efficiency: Lowers operating expenses.

-

Easy Maintenance: User-friendly designs minimize downtime.

-

Wide Application Range: Usable in agriculture, construction, automotive, and mining.

Conclusion

Hydraulic pumps play a critical role in energy transfer as the heart of the system. Hidromas provides reliable solutions to its customers with high quality and durability. In conclusion, making the right hydraulic choices determines efficiency and long-lasting performance.