Hydraulic Pumps: Piston and Gear Pump Solutions

In hydraulic systems, pumps that enable energy transfer directly determine performance and efficiency. Among them, piston pumps and gear pumps are the two most widely used types. However, each offers different advantages.

Piston Pumps

Piston pumps stand out in applications that require high pressure and flow. The reciprocating motion of the pistons pressurizes and moves the fluid.

Advantages

-

High Pressure Capacity: Piston pumps provide strong solutions in heavy industry and construction.

-

High Efficiency: They use energy effectively, minimizing losses.

-

Durability: Thanks to their robust design, they operate long-term even in harsh conditions.

Gear Pumps

Gear pumps are known for their simple and reliable design. The rotation of two gears moves the fluid.

Advantages

-

Simple Design: Easy to maintain thanks to their compact structure.

-

Low Cost: More economical compared to piston pumps.

-

Durability: Wear-resistant materials ensure long service life.

-

Continuous Flow: Delivers reliable performance in applications requiring constant flow.

Hidromas Piston and Gear Pumps

Hidromas offers a wide product range in hydraulic pump technology. With its piston and gear pumps, the company ensures high quality, durability, and performance.

Piston Pumps

Hidromas piston pumps deliver reliable performance with high pressure capacity in heavy industry, construction, and mining. Moreover, their user-friendly design provides easy maintenance and reduces operating costs.

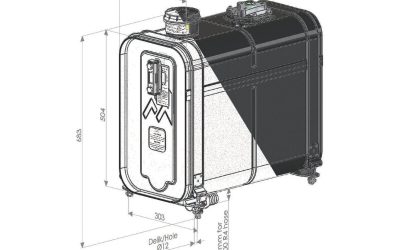

Gear Pumps

Hidromas gear pumps, with their compact structures, adapt to many industrial applications. In addition, their low cost and reliability make them an economical choice. The company also maintains high quality standards in these products.

Single and Double Rotation Gear Pumps

Gear pumps are produced in two different types: single rotation and double rotation.

Single Rotation Gear Pump

The fluid flows in only one direction. The fluid drawn in through the inlet port is discharged through the outlet port.

-

Simple Design: Suitable for small and medium-scale applications.

-

Low Cost: Lower production cost.

-

Durability: Robust body and materials ensure long life.

Double Rotation Gear Pump

Provides flow in both forward and reverse directions. The inlet and outlet ports can be switched.

-

Versatility: Easily adapts to various applications.

-

Flow Adjustment: Flow direction and control are simple.

-

High Efficiency: Saves energy and increases system performance.

Hidromas Solutions

Hidromas offers solutions that meet industry needs in both single and double rotation gear pumps. Single rotation pumps provide an economical alternative with their compact design, while double rotation pumps provide flexibility and versatility.

Conclusion

In conclusion, piston pumps are ideal where high pressure and efficiency are required, while gear pumps offer economical and simple solutions. Hidromas makes a difference in the industry by maintaining quality and reliability in both pump types.